It has a new clutch bearing and new main bearings new main crank new. Dies are properly aligned.

Side Blast Compared To Underblast Tools And Tool Making Bladesmith S Forum Board

It is completly rebuilt.

. Seems fine to work no real noticeable difference except with the side blast every now and then the thing would erupt if you left the air up too high when the coke was spent in the pot andor the sand coke clinker waste pit was getting dried out at the end of a day. Oct 30 2018 - Side blast forge. 7 12 deep and 34 tuyere for this one.

Below the air blast. This a Side Blast Forge built in the UK by Mike Judd of Greystone Forge. The swordsmith forge consists of a fuigo box bellows separated from the forge by a low wall a firepot consisting of two parallel walls to contain the fire and a charcoal reservoir where fresh charcoal is stored for use.

Its flawless design allows for superior handling. The basic design is as follows. They both work just fine.

Greystone Forge can customise any forge to your requirements or build something specific tailored to your specifications. Ive already decided on charcoal as my fuel and mostly decided on a clay-lined wood box forge design with a bottom blast. The forge has remained similar in design and purpose for thousands of years and the modern forge as we know it works essentially the same as those of its predecessors.

Having a burner on top also puts more back pressure on your system which can result in a flame escaping out of the back of your burner. Ive done a lot of research around the internet and some old books but I cant seem to find anybody who can give even a ballpark estimate of ideal dimensions. Side blast forge design To apply just adhere on the nails we like to maintain them at the base of our nail beds and set with very clear topcoat.

I have been wanting a side blast forge for a LONG time. The bottom half of the firepot area is filled with fine charcoal to provide an insulated bed for the fire and extends under the charcoal reservoir. My forge has a burner in the side at a 90 degree angle and works fine.

Japforgebmp My first question is. I want to build a side-blast forge very similar to the japanese ones. This was made by welding two.

Notice side blast. Not pictured but also included is a third hand to help with long pieces. Most of the.

In the mean time I can use it to get some practice at working some steel. Excelent for using charcoal fuel. Here it is in all.

Little giant power hammer. This text is only meant to show that a good ready-made firepot is the best option if the smith chooses a bottom air blast. Is a side draft forge same as a side blast forge or is a side draft forge a forge of any sort of blast configuration that just has a chimney that draws off to the side I suppose like the pictures Ive seen of Hofis.

A good value in my opinion. 316 Hot rolled plate material was used in the building of this traditionally British Side Blast forge however they have been built out. Side blast vs bottom blast is a non issue for charcoal.

Like shrapnel from an exploding forge this Oseram powerhouse specializes in firing armor-piercing bolts. For coal a sideblast can be more efficient since the clinker doesnt drop down and block the tuyure but charcoal doesnt produce clinker - so its not a problem anyway. Tai Goo whose videos I also recommend has a different kind of washtub forge with a side blast and the firepot made of straight wood ashes that he can reshape as needed.

Side Blast Forge Design. Whitlox forges work on the concept of making charcoal as you go. The Blast Forge Information.

Whether you need a portable forge a forge that can be kept in the corner of a shop or a full insert unit for a bricked-in forge South Side Forge will be happy to design and build a custom forge for you. At the front of the forge I included a tool rack made from 14 x 2 flat from which tongs poker or whatever can be hung. I now use a bottom blast forge made from a cast iron block.

The coke heap density in the blast furnace charge is the smallest the gap is large and the volume accounts for 35-50 of the total volume of the charge. Doesnt this design clog up with ash after a while. The biggest thing to me is insulation and where your forge doors are with a side blast I found that having a door close from the opposite side works best.

An eye-catching style hasnt been less complicated. All forges are made to order so pricing and delivery timelines will vary. Mike Deibert adapted the design for his school in Nicaragua using barrels.

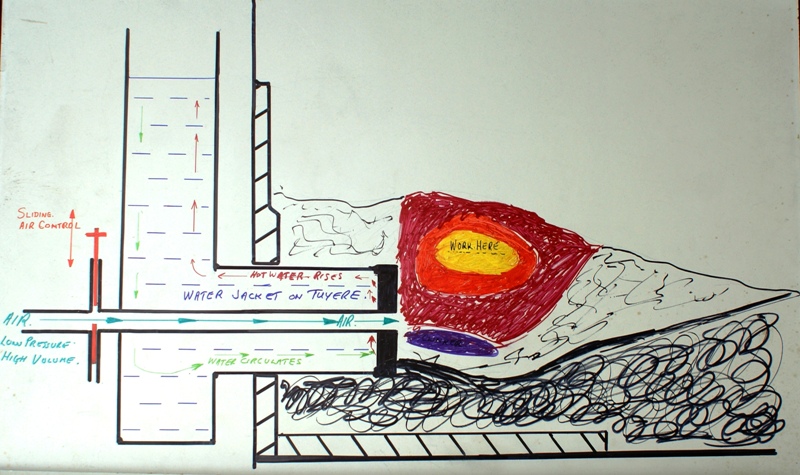

OK im confused. It shows the basic principles of a Water cooled Side Blast Forge. I dont give out prices by email.

You could have a side blast forge that has a side draft chimney too I suppose. The idea is that one day when I grow up I will be able to forge swords in it. Thanks stevefor sale is this old style 25 lb.

South Side Forge is pleased to offer custom side-blast forges to meet our customers individual requirements. The frame was cleaned to bear metal and painted with rust converter. Text or emails without contact phone number will not be replied to.

This does NOT preclude the use of the sideblast tuyere used by many smiths. Some requests have been for a smaller forge furnace mini forge special chimney designs gas forge and more. After doing a lot of research and collecting up materials I have finally built one.

The side blast forge can be fabricated by any blacksmith with the tools to cut and weld steel plate and pipe.

Side Blast Forge Excelent For Using Charcoal Fuel Forging Metal Blacksmith Projects Blacksmithing

Building A Side Blast Forge Youtube

My Side Blast Forge Design Solid Fuel Forges I Forge Iron

Folding Side Blast Forge Youtube

The 55 Forge Bottom And Side Blast Solid Fuel Forges I Forge Iron

0 comments

Post a Comment